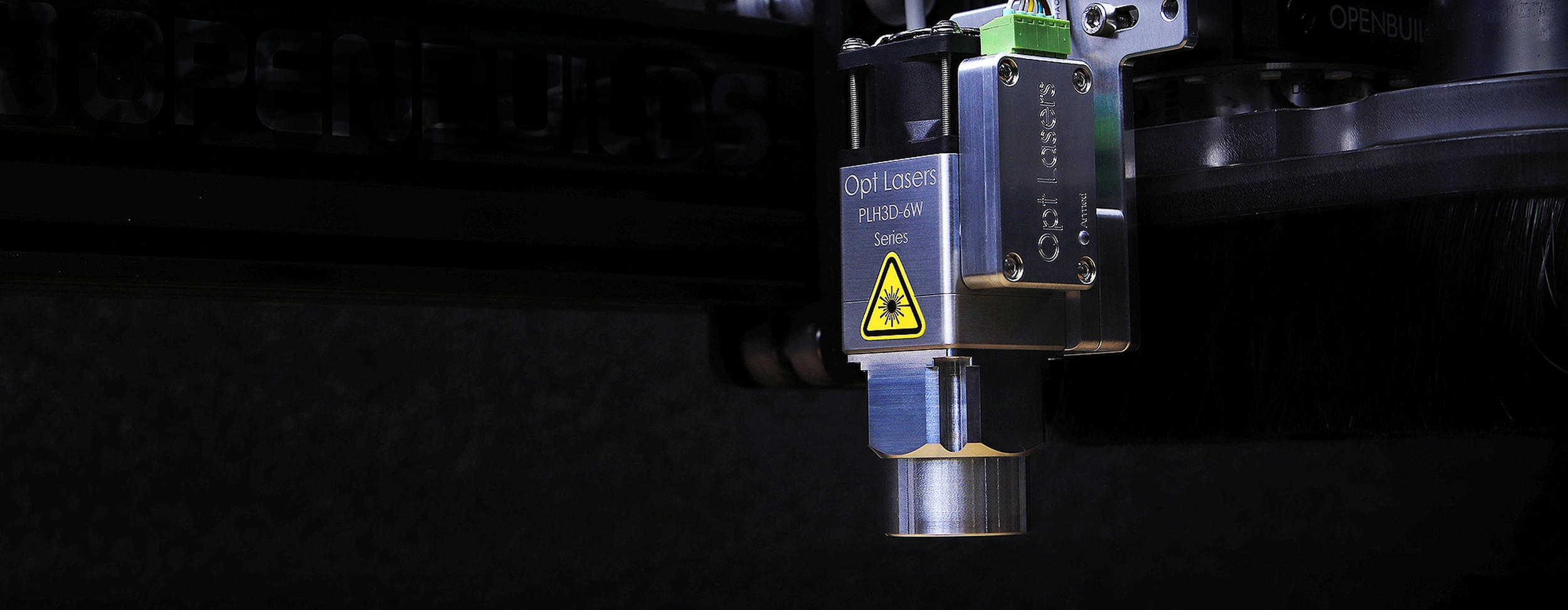

Laser marking for complex shapes and contours

SUSA S. Sauer GmbH & Co. KG uses laser marking to provide durable, abrasion-resistant markings for a wide variety of materials, complex shapes and contours. Our technology enables long-lasting markings on sensitive materials. We mark with serial numbers, logos or technical markings.

- More than 30 years of experience

- 200 qualified and experienced specialists

- Machine park of more than 100 systems

- 14,000 square meters of production space

To our certificates

To our machinery

Laser marking for every requirement

Laser marking for complex shapes and contours is an important part of the services provided by SUSA S. Sauer GmbH & Co. KG & Co KG. We rely on modern laser technology to produce precise and durable markings. We ensure an exact result even with sensitive materials or uneven surfaces.

Our non-contact processing protects the component and prevents material changes. With our service, we apply serial numbers, logos or technical markings to components, assemblies or prototypes. With years of experience and precise control, we also mark hard-to-reach areas cleanly and permanently.

As laser marking is environmentally friendly, no chemicals or additives are required for marking. This preserves the material structure and makes the marking durable. You can rely on our expertise when it comes to high-quality markings and sophisticated components. We deliver quality that impresses.

Our non-contact processing protects the component and prevents material changes. With our service, we apply serial numbers, logos or technical markings to components, assemblies or prototypes. With years of experience and precise control, we also mark hard-to-reach areas cleanly and permanently.

As laser marking is environmentally friendly, no chemicals or additives are required for marking. This preserves the material structure and makes the marking durable. You can rely on our expertise when it comes to high-quality markings and sophisticated components. We deliver quality that impresses.

Laser marking according to individual customer requirements

For us, laser marking means precisely implementing your individual marking requirements. We offer laser marking for a wide range of materials and geometries. We mark metal, plastic or glass and ensure razor-sharp and permanent markings.

Thanks to state-of-the-art laser technology, we mark small and large workpieces precisely and without contact. Even complex shapes or sensitive surfaces are no problem for us when it comes to laser marking.

We take the time to listen to your wishes and advise you personally. Every component has its own requirements and we adapt the laser marking process precisely. Our goal is perfect, long-lasting marking that meets your quality requirements. Put your trust in our experience and let us plan your marking together.

Thanks to state-of-the-art laser technology, we mark small and large workpieces precisely and without contact. Even complex shapes or sensitive surfaces are no problem for us when it comes to laser marking.

We take the time to listen to your wishes and advise you personally. Every component has its own requirements and we adapt the laser marking process precisely. Our goal is perfect, long-lasting marking that meets your quality requirements. Put your trust in our experience and let us plan your marking together.

Our service: Laser marking

We offer precise, abrasion-resistant markings on metal, plastic, ceramic and other materials - durable even under demanding conditions.

Whether one-offs or series production: We implement technical markings exactly according to specifications. Our modern laser systems guarantee razor-sharp results, even for the finest details - contactless, gentle on materials and environmentally friendly.

We provide expert advice and develop tailor-made solutions for your application. You can rely on our many years of experience and the highest quality in industrial laser marking.

Whether one-offs or series production: We implement technical markings exactly according to specifications. Our modern laser systems guarantee razor-sharp results, even for the finest details - contactless, gentle on materials and environmentally friendly.

We provide expert advice and develop tailor-made solutions for your application. You can rely on our many years of experience and the highest quality in industrial laser marking.

Request:

Laser marking

- Just send us a short message and we will be happy to answer your questions by phone or e-mail.

What is laser marking?

Laser marking is a precise process in which materials are permanently marked with a laser. At SUSA S. Sauer GmbH & Co. KG, we use state-of-the-art technology to create clear, abrasion-resistant markings. The process is suitable for metals, plastics, glass and many other surfaces.

Targeted laser pulses are used to change the material without subjecting it to mechanical stress. As a result, the surface remains intact, while the marking is resistant to abrasion, chemicals and high temperatures. Logos, serial numbers or QR codes can be implemented in razor-sharp detail.

We mark small individual parts or large series productions. Our process is fast, economical and environmentally friendly. Thanks to our experience and high-performance machines, we guarantee high-quality results that always meet your requirements.

Targeted laser pulses are used to change the material without subjecting it to mechanical stress. As a result, the surface remains intact, while the marking is resistant to abrasion, chemicals and high temperatures. Logos, serial numbers or QR codes can be implemented in razor-sharp detail.

We mark small individual parts or large series productions. Our process is fast, economical and environmentally friendly. Thanks to our experience and high-performance machines, we guarantee high-quality results that always meet your requirements.

What safety precautions must be observed during laser marking?

Laser marking requires maximum safety in order to protect people and materials. At SUSA S. Sauer GmbH & Co. KG, we rely on modern laser systems and comprehensive protective measures. Our enclosed systems prevent dangerous laser beams from escaping.

Wearing safety goggles is particularly important when working on a laser marking system, as direct or reflected beams can damage eyesight. Our laser marking machines have safety sensors that prevent unauthorized access. In addition, smoke and particles generated during laser marking are removed by powerful extraction systems.

All employees receive regular training and work in accordance with applicable safety standards. Compliance with regulations, such as the laser class and technical guidelines, is a matter of course for us. With our experience and state-of-the-art technology, we guarantee safe and precise laser marking and work reliably and professionally.

Wearing safety goggles is particularly important when working on a laser marking system, as direct or reflected beams can damage eyesight. Our laser marking machines have safety sensors that prevent unauthorized access. In addition, smoke and particles generated during laser marking are removed by powerful extraction systems.

All employees receive regular training and work in accordance with applicable safety standards. Compliance with regulations, such as the laser class and technical guidelines, is a matter of course for us. With our experience and state-of-the-art technology, we guarantee safe and precise laser marking and work reliably and professionally.

What are the advantages of laser marking compared to other methods?

Laser marking offers many advantages over conventional marking methods. We use modern laser technology to create precise, durable and environmentally friendly markings.

In contrast to mechanical or chemical processes, laser marking is contactless. As a result, there is no material wear and even sensitive surfaces remain undamaged. The markings are abrasion-resistant, heat-resistant and resistant to chemicals. In addition, even the finest details can be reproduced in razor-sharp detail.

As no inks, paints or additives are required, the process is particularly sustainable and cost-efficient. It is suitable for many materials. Our technology enables fast, flexible marking of individual items through to large series.

In contrast to mechanical or chemical processes, laser marking is contactless. As a result, there is no material wear and even sensitive surfaces remain undamaged. The markings are abrasion-resistant, heat-resistant and resistant to chemicals. In addition, even the finest details can be reproduced in razor-sharp detail.

As no inks, paints or additives are required, the process is particularly sustainable and cost-efficient. It is suitable for many materials. Our technology enables fast, flexible marking of individual items through to large series.

What types of laser marking processes are there?

There are various laser marking processes that are used depending on the material and application.

In annealing marking, the material surface is changed by the targeted application of heat, resulting in high-contrast markings. Deep engraving removes material and creates tactile, particularly resistant markings. Color change changes pigments within the material, which is particularly suitable for plastics.

Each method has its own special advantages. We select the optimum process for technical components, tool markings or decorative lettering. Laser marking from our company ensures precise, long-lasting results on a wide variety of materials. Rely on our experience and technology for the best possible quality.

In annealing marking, the material surface is changed by the targeted application of heat, resulting in high-contrast markings. Deep engraving removes material and creates tactile, particularly resistant markings. Color change changes pigments within the material, which is particularly suitable for plastics.

Each method has its own special advantages. We select the optimum process for technical components, tool markings or decorative lettering. Laser marking from our company ensures precise, long-lasting results on a wide variety of materials. Rely on our experience and technology for the best possible quality.

How environmentally friendly is laser marking?

Laser marking is a particularly environmentally friendly marking technique. At SUSA S. Sauer GmbH & Co. KG, we use state-of-the-art laser systems that do not require chemicals, ink or solvents. This means that no environmentally harmful waste or toxic residues are produced.

The process requires minimal energy and is extremely efficient. In contrast to mechanical or chemical methods, the material remains intact, meaning that no additional post-processing is required. The absence of consumables also makes laser marking sustainable and resource-saving.

Our precise markings are permanent and do not wear off, which guarantees a long service life for the marking. This saves material and reduces the need for re-marking. With our environmentally friendly technology, we offer you a clean, sustainable solution for high-quality markings that is gentle on people and nature.

The process requires minimal energy and is extremely efficient. In contrast to mechanical or chemical methods, the material remains intact, meaning that no additional post-processing is required. The absence of consumables also makes laser marking sustainable and resource-saving.

Our precise markings are permanent and do not wear off, which guarantees a long service life for the marking. This saves material and reduces the need for re-marking. With our environmentally friendly technology, we offer you a clean, sustainable solution for high-quality markings that is gentle on people and nature.

Quality at every stage of production

We guarantee our customers first-class products and absolute precision. Customer requirements guide our actions and our decisions. We do a lot to achieve this:

As a provider of CNC contract manufacturing, we always ensure the highest precision and quality. Our ISO certification ensures the consistently high standard of our quality management. We work in accordance with DIN EN ISO 9001:2015 and IATF 16949:2016. We have been certified in accordance with the environmental standard DIN EN ISO 14001 and the energy standard DIN EN ISO 50001 since 2018.

We are a manufacturer in CNC contract turning and implement the highest standards in CNC contract manufacturing. As a CNC contract manufacturer, we attach great importance to precise results that exactly meet your requirements.

- in-process inspections by qualified employees

- Use of highly developed measuring technology, e.g. 3D measuring machines, contour measuring devices, profile scanners, form measuring machines

- 100% inspection of high-volume parts for freedom from chips and important dimensions such as length, inner and outer diameter

As a provider of CNC contract manufacturing, we always ensure the highest precision and quality. Our ISO certification ensures the consistently high standard of our quality management. We work in accordance with DIN EN ISO 9001:2015 and IATF 16949:2016. We have been certified in accordance with the environmental standard DIN EN ISO 14001 and the energy standard DIN EN ISO 50001 since 2018.

We are a manufacturer in CNC contract turning and implement the highest standards in CNC contract manufacturing. As a CNC contract manufacturer, we attach great importance to precise results that exactly meet your requirements.